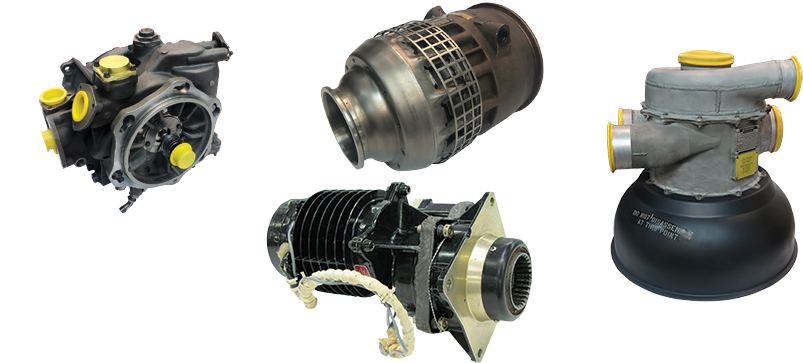

Jet Accessories Technicians, Inc. has been a global supplier of maintenance, repair, and overhaul (MRO) services for more than twenty-five years. Established in 1993, we are a Federal Aviation Administration (FAA) 145 repair... READ MORE

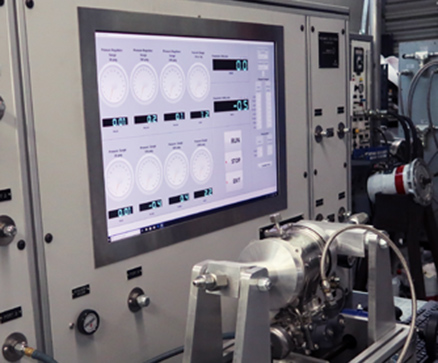

Jet Accessories Technicians, Inc. is a recognized leader in specialized aircraft component repair services, particularly fuel, hydraulic, pneumatic, power generation and electro-mechanical components. We have an extensive team of professional... READ MORE